Vehicles used to convey humans and products are meant to be created with the highest level of care. However, this isn’t always the case, as there are cases of vehicle defects owing to a design, manufacturing, or marketing flaw.

These faulty items can excessively harm vehicle users when used for their original purpose without necessary modifications or corrections.

The legal principle of product liability holds manufacturers, merchants, and sellers of a product liable for allowing defective products to reach consumers.

Defective vehicles due to specific non-functioning components can result in fatal events while driving. For example, a car malfunction could cause a fire, endangering the life of the driver and other road users.

This isn’t a strange occurrence worldwide as the US Fire Administration, in 2019, stated that up to 223,000 vehicular fires occurred, killing and injuring thousands of people.

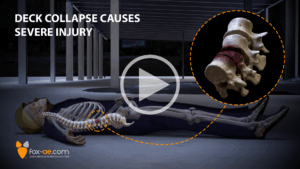

In cases like this, computer-generated animation may be used at trial to adequately demonstrate the defects in the specific elements present in the vehicle. This is known as product animation. Sometimes, there may be a need to bring out the big guns; accident reconstruction.

Common Vehicle Defects and Their Catastrophic Effects

Over the years, various automobile parts have been known to cause significant harm owing to poor production or maintenance. An instance is the case of Cronin v. JBE Olson Corp.

In this case, the claimant instituted a personal injury case claiming that the truck manufactured by the defendants was unfit for its intended purpose. This is due to manufacturing flaws, such as the metal hasp being excessively porous, containing holes, pits, and voids, and lacking the tensile strength to resist the impact. This caused him significant harm.

There are many such defects brought before the court every year. They are as follows:

- Restraint System

Automobile manufacturers have known for decades that 3-point safety belts are safer and more secure than lap belts alone. In rare cases, lap belts can potentially cause more severe injuries than if a person wore no seat belt.

It’s only recently that automakers began to provide only 3-point restraints for passengers in the center rear seat. When compared to the cost of human life, the cost of this simple modification is tiny. Still, automakers choose to preserve the old belts to save a fraction of a percent of the overall vehicle’s value in profit.

- Counterfeit Child Restraints

Child seat makers, unfortunately, are held to much lesser requirements than automobile manufacturers. Though these gadgets are designed to safeguard children, thousands of unfortunate and senseless fatalities and catastrophic injuries are caused by less rigorous testing procedures and quality standards.

- Rollover Roof Crush

Thousands of people die every year due to rollover crashes involving roof crushes. Although Electronic Stability Control is not currently commonplace in most vehicles, it has been known since the technology’s inception that it significantly reduces the number of rollover crashes. Manufacturers have also slashed corners and saved money on roof strength, resulting in roofs that are prone to collapse, resulting in deaths and serious injuries.

- Defective Tires/Aging Tires

Tire problems are generally disguised due to the nature of these commodities until the tire fails; this is usually horrifically. Tires are another prominent source of preventable automotive accidents, as the controversy involving Ford Explorer rollover incidents and the Firestone tires debacle.

A buyer has virtually no way of knowing at the time of purchase whether a manufacturer has opted to use less expensive, less reliable elements and formulations to save money. When the tire is under stress, such as during an emergency maneuver to prevent an accident, it frequently results in a massive tire breakdown.

Tires should always be replaced after six years of service, even if they were correctly built. On the other hand, tire manufacturers frequently fail to inform the public about this critical maintenance necessity.

- Defective Materials Causing Vehicle Fires

Failure to include anti-siphoning valves, failure to protect gasoline lines, failure to include fuel filler tubes, misrouting of fuel lines, and location of the fuel tank within the vehicle’s crush zone are all reasons for vehicle fires. Post-collision flames are the most significant cause of vehicle-related mortality.

Using Computer Generated Animation in Vehicle Defect Cases

The first point to remember is that the vehicle manufacturer, the manufacturer of the specific part of the vehicle, or the owner can all be held liable for the vehicular defect.

Regardless of who would be held liable, computer-generated animation can be used to display the defective product and how it functions and a standard product with no defects and the proper way it is expected to function.

Sometimes, computer-generated animation is not enough. In the circumstances like this, there may be a need to consider an accident reconstruction of the incident. In cases like this, consulting with an experienced vehicle defect animation company is essential to know the best course of action.